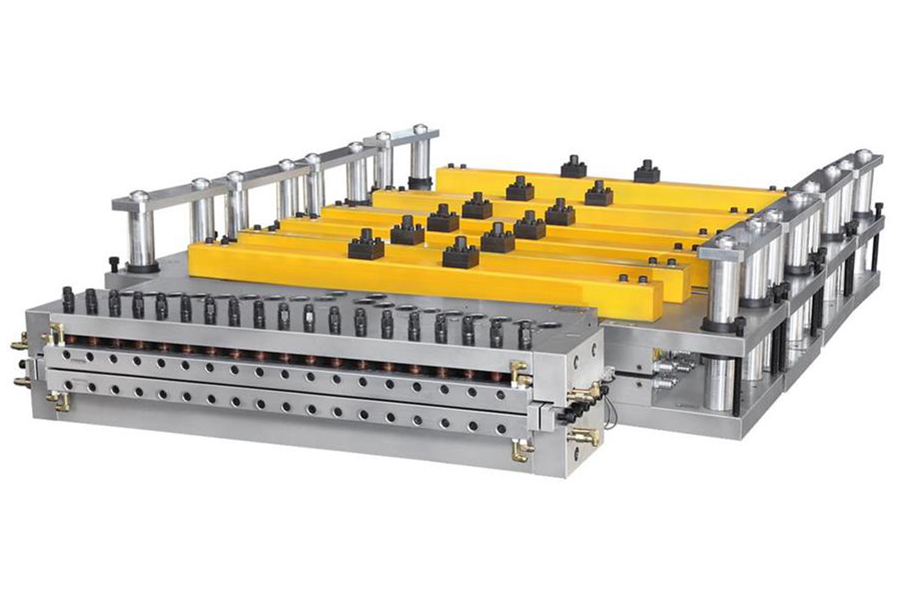

Factory Price For Anti-rust mould - PVC Foam Board without Choke bar Single-layer Mould – Weilei

Factory Price For Anti-rust mould - PVC Foam Board without Choke bar Single-layer Mould – Weilei Detail:

|

Name |

PVC FOAM BOARD WITHOUT CHOKE BAR SINGLE-LAYER MOULD |

|

Size |

Customized |

|

Cavity |

Single-layer |

|

Plastic Material |

PVC |

|

Main application |

Cabinets board, furniture board, decoration board, floor board, building board, bricks trays, etc. |

|

Thickness |

3-30 mm |

|

Applicable product width range |

450-2500 mm |

|

Product Type |

PVC Foam Board. |

|

Mould Guarantee |

1 year |

|

Mould Component |

Die head, heating rod, calibrator, Flange |

|

The Production Cycle |

30-45 days |

|

Surface Treatment |

Polish |

|

Package & deliver |

Wood case for exporting, each mould will be cleaned before packing. |

1. Our PVC foam board mould:

A) Die design is based on flow simulations on our computer, flow analysis and experience, that leads to excellent flow characteristics. Original runner way technology to provide prerequisite for high-speed extrusion.

B) High precision positioning pin design guarantees accurate plate assembly. Runner system and inner cavity are mirrored and polished to make the products more bright.

2. Calibrator: High cooling speed low hauling resistance to supply exact security for products calibration.

3. Using the removable locating pin devices.

4. The channel design has avoided the dead area and retention.

5. The optimized design of the flowing channel gives it a stronger impact resistance.

6. The mould has high stability and high extrusion speed.

7. Easy to assemble and disassemble.

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Factory Price For Anti-rust mould - PVC Foam Board without Choke bar Single-layer Mould – Weilei , The product will supply to all over the world, such as: Croatia, Benin, Qatar, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.